Leave Your Message

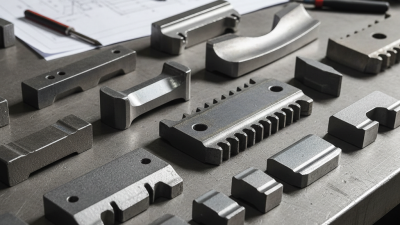

Stainless Steel Castings have become vital in modern industries. These castings are known for their durability and resistance to corrosion. As technology advances, the applications of stainless steel castings are expanding significantly.

In sectors like automotive and aerospace, stainless steel castings play a crucial role. They are used in components that need strength and reliability. Moreover, in the construction industry, stainless steel castings provide structural integrity. Their ability to withstand harsh environments adds to their appeal.

Despite their advantages, there are challenges. The cost of stainless steel castings can be high. This might limit their use in some applications. Additionally, the casting process requires skilled labor, which may not always be available. Recognizing these challenges can lead to better solutions and innovations in future applications.

Stainless steel castings play a vital role in modern industries. These components excel in durability, corrosion resistance, and versatility. According to a recent industry report, the global stainless steel market is projected to reach $200 billion by 2025, driven by these advantageous properties. In sectors like automotive, construction, and aerospace, stainless steel castings provide the reliability needed for critical applications.

Specific applications highlight their importance. In the automotive sector, for example, stainless steel castings are used in exhaust systems and structural components. The ability to withstand high temperatures is crucial here. Another sector benefiting significantly is healthcare. Surgical instruments often rely on stainless steel castings for their strength and effectiveness. However, these castings can sometimes fall short in precision manufacturing, leading to wastage and inefficiencies.

Reflecting on the production processes, manufacturers must confront challenges like high energy consumption during casting. Moreover, while stainless steel provides longevity, its production can be resource-intensive. As industries evolve, the focus on sustainability becomes essential. Proper recycling measures and energy-efficient processes need to be developed. This balance will enhance the ongoing significance of stainless steel castings in modern manufacturing environments.

Stainless steel castings hold unique advantages in various industries. Their corrosion resistance is one of the most sought-after characteristics. Reports indicate that stainless steel can withstand harsh environments. This feature is critical in sectors like chemical processing and marine applications. An estimated 70% of new industrial equipment relies on stainless steel components due to their durability.

Another key characteristic is their ability to maintain structural integrity at high temperatures. Stainless steel castings can perform in temperatures exceeding 1,000 degrees Fahrenheit. This makes them ideal for power generation and aerospace fields. However, while the thermal stability is impressive, the cost of production can be high when compared to other materials.

In terms of aesthetics, stainless steel offers superior finishing options. Its shiny surface can enhance product appeal. Manufacturers report that products with stainless steel castings see a higher market acceptance. Despite these benefits, some casting techniques still need refinement. Post-processing methods can sometimes lead to surface imperfections that require additional work. Therefore, attention to detail is crucial in achieving high-quality stainless steel components.

| Application | Key Characteristics | Industries |

|---|---|---|

| Aerospace Components | High strength-to-weight ratio, corrosion resistance | Aerospace |

| Marine Equipment | Excellent corrosion resistance in saltwater | Marine |

| Automotive Parts | Durability, heat resistance, lightweight | Automotive |

| Food Processing Equipment | Hygienic, easy to clean, rust-resistant | Food & Beverage |

| Medical Instruments | Biocompatibility, corrosion resistance | Healthcare |

| Construction Materials | Strength, durability, aesthetic appeal | Construction |

| Power Generation Components | Wear resistance, temperature tolerance | Energy |

| Chemical Processing Equipment | Corrosion resistance, high strength | Chemical |

| Telecommunications Hardware | Durability, low maintenance | Telecommunications |

| Railway Parts | Strength, fatigue resistance | Transportation |

The aerospace sector demands materials that offer exceptional performance and reliability. Stainless steel castings are increasingly valued for these qualities. They provide strength and corrosion resistance, essential for withstanding extreme conditions. Aircraft components, such as landing gear and structural parts, often utilize these castings to enhance durability.

However, challenges exist. The balance between weight and strength remains a concern. Engineers must constantly refine designs to maintain optimal performance while reducing mass. Each casting process can lead to variability in mechanical properties. Quality control measures are crucial but often complex. Despite advancements, achieving flawless consistency in production is not guaranteed. This aspect invites further exploration and innovation in casting techniques.

The integration of stainless steel castings in the aerospace sector symbolizes modern engineering advancements. Yet, ongoing scrutiny into these materials highlights the need for continuous improvement. Designers face the challenge of pushing boundaries while ensuring reliability in every component. The path to perfection is ongoing, and the industry must remain adaptable.

The automotive industry increasingly relies on stainless steel castings. These components are known for their strength and corrosion resistance. In fact, about 20% of automotive parts now use stainless steel castings. This trend reflects a growing demand for durability and longevity.

Innovative applications include exhaust systems, brackets, and valve components. These parts benefit from the lightweight nature of stainless steel, which enhances fuel efficiency. As noted by industry reports, reducing vehicle weight by just 10% can improve fuel economy by 6-8%. This impacts not only performance but also environmental goals.

However, challenges exist. Production costs for stainless steel castings can be higher than traditional materials. Additionally, some manufacturers struggle with sourcing high-quality alloys consistently. Improvements in supply chain management are essential. As the industry evolves, it must address these issues to fully utilize the potential of stainless steel in automotive applications.

Stainless steel castings play a crucial role in the food and beverage industry. Its ability to resist corrosion and withstand high temperatures makes it ideal for various applications. According to a recent report, nearly 70% of the food processing industry relies on stainless steel components in equipment. This is due to its inherent safety features and compliance with stringent health standards.

The unique properties of stainless steel help prevent contamination. However, improper maintenance can lead to issues. For instance, not regularly cleaning stainless steel surfaces can result in the build-up of unwanted bacteria. Indeed, a study highlighted that 60% of foodborne illnesses are linked to improper sanitation practices. This emphasizes the importance of not only using quality materials but also ensuring consistent upkeep.

Moreover, while stainless steel complies with many safety regulations, manufacturers must remain vigilant. The FDA mandates specific grades of stainless steel for food contact. Not adhering to these standards can lead to serious repercussions. Regular audits can help mitigate these risks but may not be foolproof. Industry experts stress the importance of ongoing training for operators to maintain safety in processing.