Leave Your Message

Choosing the right Nickel Alloy for a project can be daunting. Experts like Dr. Emily Tran emphasize, "Understanding the specific requirements is key." Nickel Alloys are essential in various industries due to their unique properties. They resist corrosion and maintain strength at high temperatures.

Many factors influence the choice of Nickel Alloy. You must consider the environment where it will be used. Is it a marine application or high-temperature processing? Each scenario demands different properties. Sometimes, the options can feel overwhelming. One must prioritize quality while staying within budget.

Mistakes can happen during selection. An alloy might not perform as expected, leading to project delays. Reflecting on past experiences can guide future choices. It’s crucial to learn from these moments to improve decision-making. In the end, the right Nickel Alloy can make all the difference.

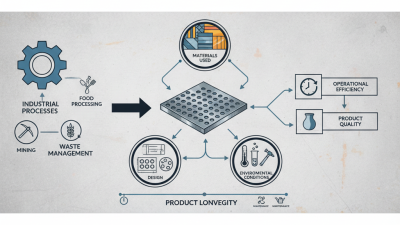

When selecting a nickel alloy for industrial applications, several factors come into play. The environment in which the alloy will be used is crucial. Will it be exposed to high temperatures or corrosive substances? Different alloys perform better under various conditions. For example, some offer excellent resistance to oxidation, while others excel in acidic environments.

Another important factor is mechanical properties. The strength and ductility of an alloy significantly affect its performance. If your project requires parts that endure heavy loads, selecting an alloy with high tensile strength is vital. Conversely, if flexibility is needed, a more malleable alloy would be preferable. Evaluating your project's requirements precisely is not always straightforward.

Cost considerations also influence alloy selection. Some nickel alloys can be expensive to source. Balancing performance with budget constraints often leads to difficult choices. A seemingly optimal alloy may not fit financially. It's essential to weigh these trade-offs carefully. Always revisit your choices with a critical eye. Perfect solutions are rare, and adjustments may be necessary along the way.

Nickel alloys are essential in many industrial applications. Understanding their types and properties helps in making an informed choice for your project.

Common nickel alloys include Inconel, Monel, and Hastelloy.

Inconel is known for its high-temperature strength and oxidation resistance. It is often used in aerospace and chemical processing.

Monel, on the other hand, excels in corrosion resistance. Its applications include marine environments and chemical industries.

Hastelloy shines in extreme conditions. It's resistant to pitting and stress corrosion cracking. Ideal for chemical processing, it can handle harsh environments.

When choosing an alloy, consider several factors. Think about temperature, corrosion resistance, and mechanical properties. Some projects may require specific grades.

Not every alloy is perfect for every application. This can lead to failures if not carefully considered.

Therefore, always evaluate the project needs thoroughly. Allow space for adjustments in your choice.

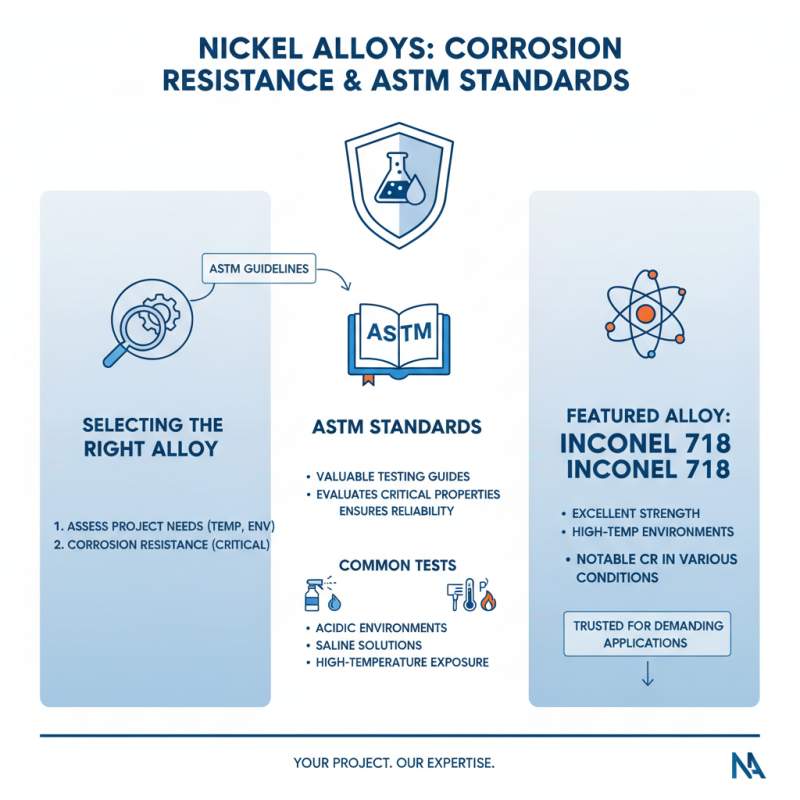

Selecting the right nickel alloy for your project requires careful assessment, especially regarding corrosion resistance. ASTM standards offer valuable guidelines for evaluating these properties. For instance, alloys like Inconel 718 are known for their excellent strength in high-temperature environments. Their corrosion resistance is often tested under various conditions, including acidic and saline environments.

Corrosion resistance is crucial. The ASTM G48 standard tests pitting resistance in stainless steels and nickel alloys. It helps identify the alloy's performance in chloride environments. Research shows alloys that comply with these standards generally exhibit significantly lower failure rates. For example, ASTM B165 specifies requirements for nickel alloy pipes, ensuring they withstand corrosive services effectively.

**Tip:** Always compare data from multiple tests before making a choice. Consider the environment your alloy will face. Multiple factors, like temperature and pH, can influence corrosion outcomes. Consulting detailed ASTM reports can help clarify which alloy suits your needs best. Understand that corrosion behavior can vary, leading to unexpected challenges. Thus, careful selection and continuous evaluation are vital.

When considering nickel alloys for your project, cost plays a critical role. Prices can vary significantly based on alloy composition and market demand. Not all nickel alloys are equally priced; some are more expensive due to their unique properties. For instance, alloys with high corrosion resistance often come at a premium. It's essential to evaluate your project requirements against these costs.

Availability is another key factor. Nickel alloy supply can be influenced by various factors, including production capacity and geopolitical issues. Sometimes, certain alloys may not be readily available, leading to delays. If you find yourself in this position, alternative materials might need exploration. This can lead to unexpected compromises on project timelines or specifications. It’s vital to keep an open mind about substitutions, but ensure they meet essential performance standards.

Balancing cost and availability often involves tough decisions. You may have to prioritize specific properties over budget constraints or vice versa. Conduct thorough market research to identify trends and potential price fluctuations. Keeping an ongoing dialogue with suppliers can also help in anticipating these changes, aiding better planning ahead of any project milestones.

Nickel alloys are crucial in aerospace applications. They withstand extreme temperatures and resist corrosion. These properties are essential for parts like turbine blades and combustion chambers. The durability of nickel alloys ensures reliability in high-stress environments.

In high-temperature settings, nickel alloys maintain structural integrity. They resist oxidation and thermal fatigue. This makes them suitable for gas turbine engines. However, selecting the right nickel alloy can be challenging. Different alloys have varied responses to environmental stress. It’s important to consider specific project requirements.

Understanding the conditions of your application is vital. Test samples in real-life scenarios can provide insights. Monitoring performance will help identify any weaknesses. Sometimes, the best choice might still lead to failures. Learning from these experiences improves future selections.

| Nickel Alloy | Composition (% Nickel) | Key Properties | Typical Applications | Temperature Range (°C) |

|---|---|---|---|---|

| Inconel 625 | 58 | High strength, oxidation resistance, weldability | Aerospace, marine, chemical processing | -200 to 980 |

| Inconel 718 | 52 | Excellent fatigue strength, corrosion resistance | Gas turbine components, aerospace engineering | -253 to 704 |

| Monel 400 | 67 | Good corrosion resistance, high strength | Chemical processing, marine applications | -100 to 540 |

| Hastelloy C-276 | 57 | Excellent resistance to pitting and stress corrosion | Chemical processing, pollution control | -196 to 1040 |