Leave Your Message

Choosing the right casting fittings is crucial for the success of any project. These components are often small but play a significant role in the overall functionality of your design. When selecting casting fittings, consider the materials used in their construction. Various materials come with unique properties and applications.

The market offers a wide variety of casting fittings, making the selection process overwhelming. It’s easy to become distracted by options that look appealing but may not meet project requirements. Always assess the specific needs of your project. Think about durability, weight, and resistance to environmental factors. This will lead to better choices.

Pay attention to the specifications of each fitting. Sometimes, the right choice isn't the most visually appealing. Reflection on practical needs can lead to unexpected yet effective solutions. Mistakes often arise from haste. Rushing to make decisions might leave gaps in your project. Take your time to evaluate all available options carefully.

Casting fittings are crucial components in various projects, including plumbing and construction. They come in different types, each with specific applications. Common types include elbows, tees, and reducers. Elbows change the direction of pipes, while tees allow for branch connections. Reducers enable the transition between different pipe sizes.

Choosing the right type of fitting can be challenging. It's important to consider the project's requirements and the intended use of the fittings. For example, high-pressure applications may need durable materials. Pay attention to fitting sizes to ensure proper connections. Mismatched sizes can lead to leaks and inefficiencies.

**Tips:** Always measure twice before purchasing. Sketch your piping layout to visualize fitting needs. Don't overlook the importance of materials; different environments require specific properties like resistance to corrosion. Testing the fit on a small scale can save you frustration later. Remember, even experienced professionals make mistakes, so stay open to adjusting your plans.

This chart illustrates the distribution of various types of casting fittings and their applications in different industries, helping you understand which fittings may best suit your project requirements.

When selecting casting fittings for your projects, the material is crucial. Materials can vary from metal to plastic. Each option offers different strengths and weaknesses. Metal fittings are strong but may corrode over time. Plastic is lighter but can be less durable. Consider the environment where the fittings will be used. You want a material that will withstand specific conditions.

Next, think about compatibility. Not all fittings work with every type of pipe or equipment. Mismatches can lead to leaks and failures. Measure your dimensions accurately before making a decision. A fitting that appears perfect might not fit correctly in practice. It’s essential to test fit some options when possible.

Lastly, assess your project requirements. Are you looking for high pressure resistance? Or is flexibility more important? Reflect on past projects that went wrong. Learning from mistakes helps in making better choices. Sometimes, it’s about finding a balance between cost and quality. Don’t rush your decision; take time to evaluate different options.

| Factor | Description | Importance Level |

|---|---|---|

| Material | Choose the appropriate material based on chemical exposure and temperature. | High |

| Design Compatibility | Ensure fittings match the design requirements of the project. | Medium |

| Size and Dimensions | Accurate measurements are essential for proper fit and function. | High |

| Coating and Finish | Select appropriate coatings to prevent corrosion and enhance durability. | Medium |

| Installation Requirements | Consider installation methods and tools needed for the fittings. | High |

| Regulatory Compliance | Ensure that the fittings comply with relevant industry standards. | High |

Choosing the right material for casting fittings is crucial. Iron, aluminum, and other options each have distinct properties. Iron is strong but heavy. It performs well under high stress. Yet, it can rust and may require coatings.

Aluminum is lighter and corrosion-resistant. This makes it suitable for various applications. Industry reports suggest that aluminum casting represents nearly 25% of the market. Its malleability allows for complex shapes, but it may not withstand extreme conditions as well as iron.

Other options, such as magnesium and zinc alloys, can be beneficial. Magnesium is lightweight yet strong. However, it is susceptible to corrosion. Zinc offers great casting fluidity, but it is less durable. Evaluating these factors helps in making informed choices.

Choosing the right casting fittings for your projects is crucial. Sizing and compatibility are essential factors to consider. A tight fit can ensure efficiency, while an oversized part may cause leaks or inefficiencies. It's tempting to pick something that looks good. However, functionality should come first.

When you measure for fittings, take your time. Rushing can lead to mistakes. Perhaps you may overlook certain dimensions. Check the specifications multiple times. A simple error can derail your entire project. Compatibility with existing systems is also vital. If parts don't mesh well, it can lead to frustration later.

Visualize how everything connects. Picture the flow and how each piece plays a role. It can be complex. You might even discover that your first choice isn't the best fit. This reflection will help achieve better results. Remember, ensuring a proper fit saves time and resources in the long run.

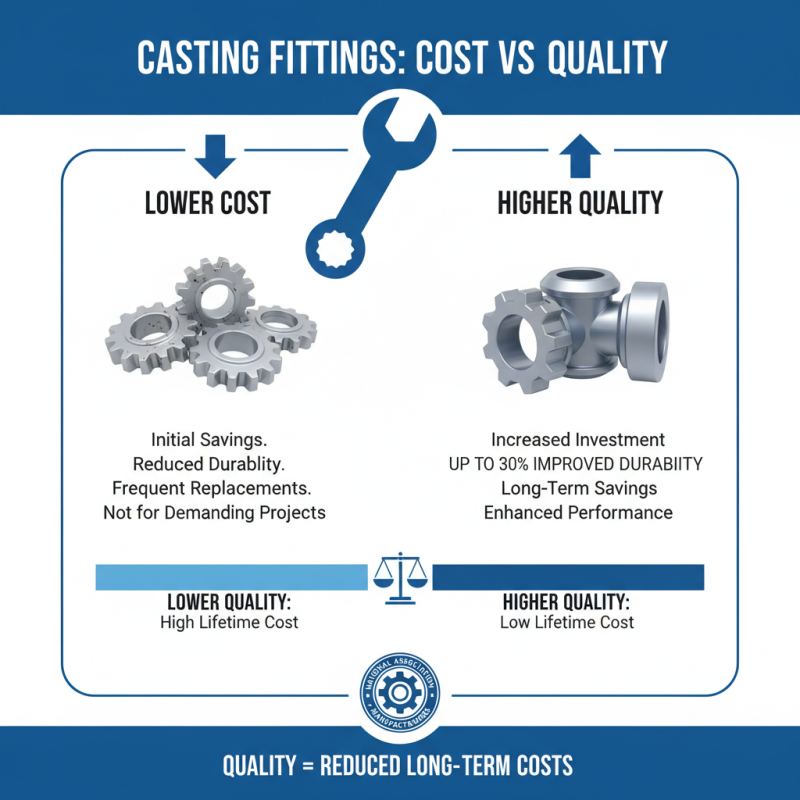

When selecting casting fittings, balancing cost and quality is crucial. Investing in high-quality fittings typically reduces long-term costs through improved performance. A recent industry report from the National Association of Manufacturers highlights that quality fittings can improve durability by up to 30%, minimizing replacements. However, lower-cost options may initially seem appealing. They often lack the quality necessary for demanding projects.

Tip: Always assess the project requirements before making a decision. Consider the environment and expected wear and tear. Environmentally harsh conditions may justify higher quality investments. Sometimes, lower upfront costs can lead to higher maintenance expenses down the road.

It's important to reflect on the ultimate goals of your project. Determine your budget constraints and quality expectations early on. A clear understanding helps avoid costly mistakes later. Conduct thorough research on the materials involved. Overlooking material properties could lead to unexpected failures.

Tip: Gather feedback from industry professionals. Their insights can reveal the hidden costs tied to cheaper options. Prioritize quality for critical applications while remaining conscious of budget limitations. Quality doesn’t always come with a premium price tag.