Leave Your Message

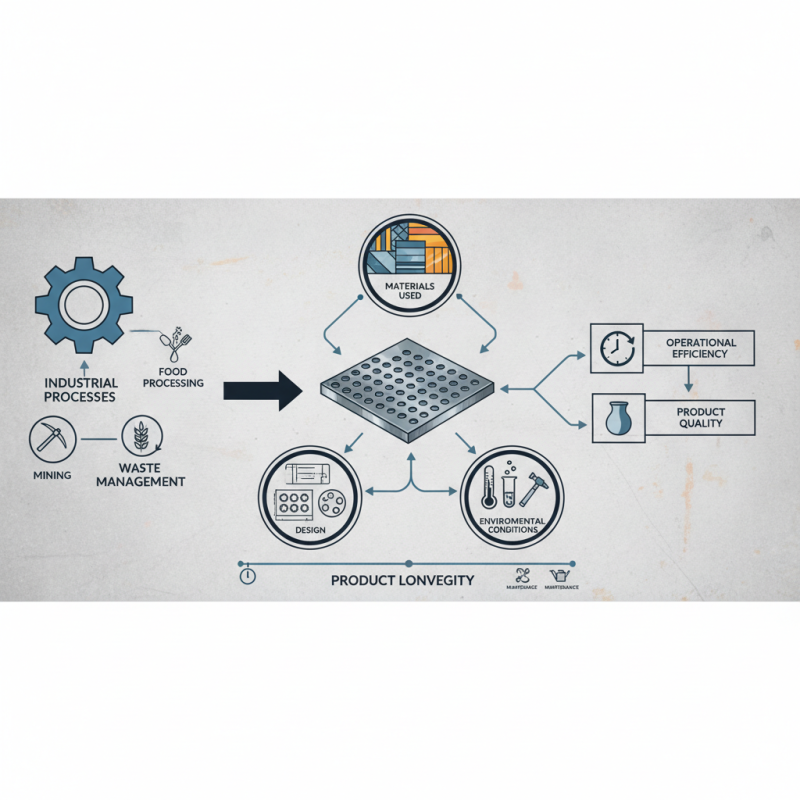

When it comes to selecting the right equipment for industrial processes, one often overlooked component is the abrasion resistant sieve plate. This essential tool plays a crucial role in various applications, including mining, food processing, and waste management, where materials are constantly subjected to harsh conditions. Choosing the best abrasion resistant sieve plate tailored to your specific needs can significantly impact your operational efficiency and product quality.

Understanding the key factors that influence the performance and durability of an abrasion resistant sieve plate is vital. These factors include the materials used in construction, the design of the sieve plate, and the specific environmental conditions in which it will be utilized. Whether you require a sieve plate that can withstand high temperatures, corrosive substances, or the rigors of heavy-duty processing, making an informed decision will ensure that you invest in a solution that meets your requirements and minimizes downtime.

In this article, we will explore the various aspects you need to consider when selecting an abrasion resistant sieve plate, including material selection, maintenance requirements, and product longevity. By gaining insights into these important elements, you will be better equipped to choose the right sieve plate that not only withstands wear and tear but also enhances the overall performance of your operations.

Abrasion resistance is a critical factor to consider when selecting sieve plates for various industrial applications, as it directly impacts the longevity and efficiency of the equipment. Sieve plates experience significant wear due to the abrasive materials they come into contact with. Reports indicate that materials subjected to high wear conditions can lead to a reduction in sieve performance by up to 30% over time if not properly managed. Understanding the underlying materials that enhance abrasion resistance, such as hard coatings or specific alloys, is fundamental for industries ranging from mining to food processing.

Research published in the Journal of Materials Science highlights that alloy composition and surface treatments can dramatically improve the abrasion resistance of sieve plates. For instance, sieve plates made from high-carbon steel or those that undergo hardening processes can exhibit over 40% greater durability compared to standard materials. Additionally, evaluating the operating conditions—such as particle size and speed of material flow—will help in selecting the right sieve plate that meets specific operational demands. The incorporation of testing methods, such as the ASTM G65, further facilitates the assessment of abrasion resistance, offering standardized criteria for performance evaluation.

When selecting the best abrasion resistant sieve plate for your specific applications, understanding the key materials utilized is paramount. Different materials provide varying levels of durability, performance, and resistance to wear, which are crucial for industries dealing with coarse particles and harsh environments. The most commonly employed materials include high-carbon steel, stainless steel, and specialized alloys. According to a report by the National Institute of Standards and Technology (NIST), high-carbon steel sieve plates offer excellent resistance to abrasion while maintaining a cost-effective profile, making them a popular choice for general applications.

Stainless steel, particularly those hardened with additional treatments, proves to be another strong candidate for sieve plates. Its inherent resistance to corrosion combined with high abrasion resistance makes it suitable for handling materials in chemical processing and food industries, where hygiene is a concern. The ASTM International has published data indicating that sieve plates made of stainless steel can withstand up to 15% longer wear time compared to traditional carbon steel plates under similar operating conditions. Also, specialized alloys, like nickel-based composites, are increasingly gaining traction for their exceptional performance in highly abrasive and extreme temperature environments, showcasing an up to 30% increase in lifespan compared to conventional materials.

Ultimately, the choice of material for abrasion resistant sieve plates should be guided by the specific requirements of the application, including the type of materials being processed and the operating conditions. By evaluating these factors, industries can make informed decisions that enhance productivity and reduce maintenance costs over time.

When selecting the best abrasion-resistant sieve plate for your specific needs, understanding mesh sizes is crucial. Different applications require different mesh sizes to effectively separate materials based on their particle sizes. For example, in food processing, a finer mesh may be necessary to ensure that contaminants are removed, while in industrial applications, a coarser mesh may be sufficient to handle larger granules. Thus, evaluating the intended use of the sieve plate is key to optimizing performance.

Tips for selecting the right mesh size include considering the material properties and the desired outcome of your sifting process. For lighter, dust-like substances, opting for finer meshes can help capture even the smallest particles. Conversely, for heavier materials like aggregates, a coarser mesh could facilitate quicker throughput without risking clogging. Additionally, always consider the aperture shape; square or rectangular openings can influence the efficiency of particle separation.

Another important factor is the abrasion resistance of the mesh material itself. When dealing with harsh and abrasive materials, selecting a sieve plate made with durable materials will enhance its lifespan and reduce the frequency of replacements. Keeping these considerations in mind ensures that you choose a sieve plate that not only meets your mesh size requirements but also withstands the rigors of your particular sifting applications.

When selecting an abrasion-resistant sieve plate, understanding its durability and maintenance requirements is essential for ensuring prolonged service life and optimal performance. Durability is primarily determined by the material composition of the sieve plate. High-quality materials that resist wear and tear not only withstand abrasive materials but also maintain structural integrity over time. When assessing durability, consider factors such as the thickness of the plate, the type of coating used, and the overall design which can influence its resistance to physical stress during operations.

Maintenance needs are another critical aspect to consider. An ideal sieve plate should not only be durable but also easy to maintain. Regular inspections and cleanings can significantly extend the lifespan of the sieve plate, preventing the accumulation of residue that may hinder performance. It is advisable to choose a sieve plate design that facilitates easy disassembly and cleaning, reducing downtime during maintenance. By prioritizing durability and maintenance ease, users can ensure that their sieve plates operate efficiently and meet the demands of their specific applications.

When it comes to selecting the right supplier for your abrasion resistant sieve plates, quality should be your top priority. A reliable supplier not only provides durable products but also understands the specific requirements of your industry. Look for suppliers who have a strong reputation in the market, as verified by customer testimonials and case studies. It is beneficial to choose suppliers who specialize in the materials and designs that best suit your needs, ensuring that you receive products that perform effectively under varying conditions.

Tips: Always ask for detailed product specifications and inquire about the manufacturing process. A good supplier should be transparent and willing to share information about how their sieve plates are made, including the type of abrasion resistant materials used. Additionally, consider suppliers who offer comprehensive after-sales support and warranties, as this reflects their commitment to quality and customer satisfaction.

Quality assurance is another crucial factor when selecting a supplier. It is advisable to choose suppliers that adhere to recognized industry standards and certifications. This not only guarantees the reliability of the products but also shows that the supplier is dedicated to continuous improvement and customer service. Engaging with suppliers who are willing to participate in ongoing communication can deepen your partnership and help ensure that you receive the best possible service alongside high-quality sieve plates.