Leave Your Message

Choosing the right crusher blade is a critical decision for anyone involved in material processing and size reduction industries. With a vast array of options available on the market, understanding the specific requirements of your operations is essential for optimal performance. The right crusher blade not only enhances efficiency but also reduces operational costs and prolongs the lifespan of your machinery. Therefore, selecting a blade that aligns with your processing needs can significantly influence overall productivity.

When tasked with finding the perfect crusher blade, there are several factors to consider, including material compatibility, blade design, and the type of materials being processed. Each application may require a distinct design to achieve desired results, making careful consideration crucial. This guide aims to provide you with the top ten tips for choosing the right crusher blade, ensuring that you make an informed decision that meets your operational demands while maximizing performance.

When selecting the right crusher blade, understanding the various types available in the market is crucial for optimizing performance and efficiency.

Crusher blades come in several designs, including single and double shaft blades, which cater to different materials and processing needs. According to industry reports, the global crusher blade market is projected to grow at a CAGR of 5.2% from 2021 to 2026, driven by increasing demand in recycling and waste management sectors.

One important tip for choosing a crusher blade is to consider the material compatibility. Blades made from high-carbon steel are optimal for shredding tougher materials, while those crafted from stainless steel may serve better in applications requiring corrosion resistance.

Another critical aspect is the blade geometry; certain shapes can enhance cutting efficiency and reduce wear over time.

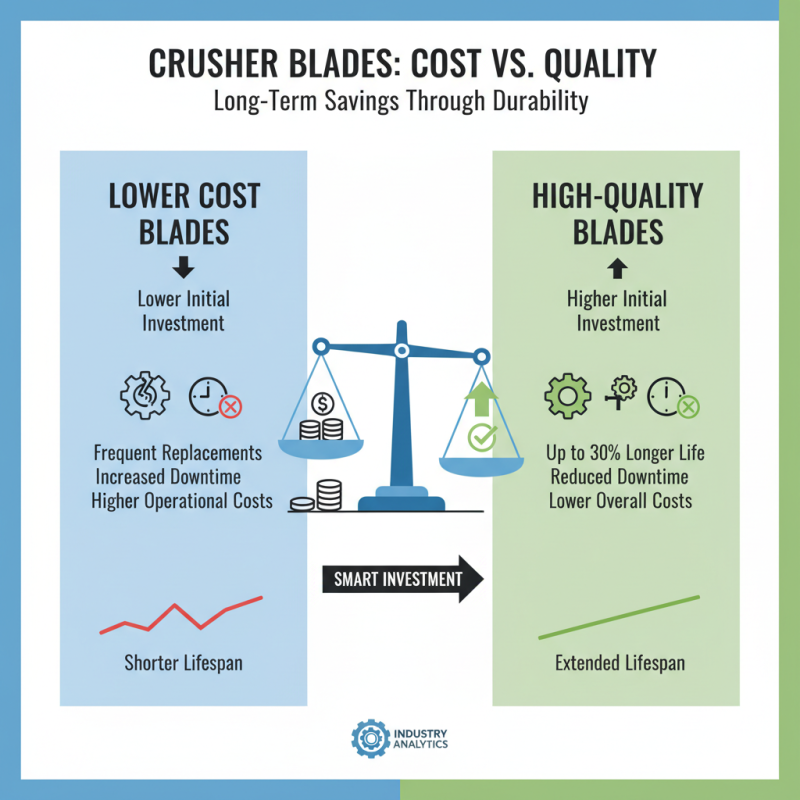

Additionally, it's essential to evaluate the blade's maintenance requirements to ensure longevity and consistent performance. An effective blade should not only be durable but also designed for easy replacement. Research indicates that properly maintained blades can last up to 30% longer, reducing operational costs and downtime dramatically.

By understanding these various types and features of crusher blades, users can make informed decisions that align with their specific processing needs.

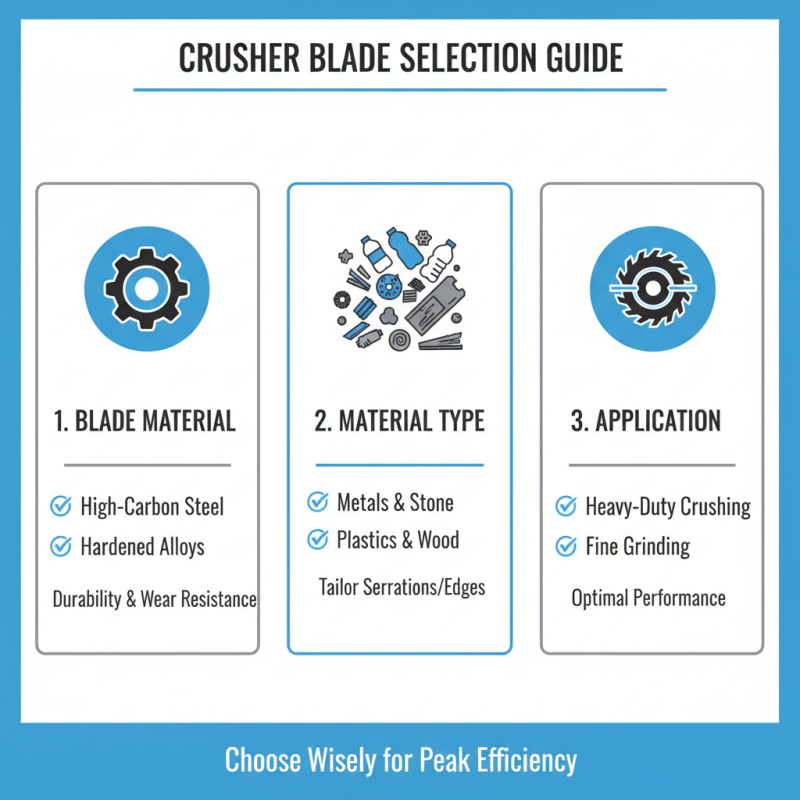

When selecting a crusher blade, several key factors must be considered to ensure optimal performance for your specific applications. Firstly, the material of the blade plays a critical role in its durability and effectiveness. Blades made from high-carbon steel or hardened materials tend to offer greater wear resistance, which is essential for heavy-duty tasks. Moreover, understanding the type of materials you will be processing can guide you in choosing blades with specific serrations or cutting edges tailored to those materials.

Another crucial factor is the blade design and configuration, which can significantly influence the efficiency of the crushing process. It's important to assess the blade shape — whether you need straight edges for precision cuts or curved edges for a more aggressive approach. Additionally, the size and thickness of the blade can affect both the power needed to operate the machine and the end product's size.

Tip: Always evaluate the intended application; different operations require different blade properties to function optimally. For instance, a blade used for recycling plastics may not be suitable for crushing metals. Furthermore, consider the blade's compatibility with your existing machinery, as the right fit will enhance performance and longevity. Seeking expert advice and conducting thorough research will help you make an informed choice tailored to your specific needs.

When selecting crusher blades, assessing material compatibility is paramount for ensuring optimal performance. Different materials exhibit varying characteristics, such as hardness, moisture content, and abrasiveness, which can significantly impact the efficiency and longevity of the blades. For instance, abrasive materials may wear down softer blades quickly, necessitating the selection of more durable options made from high-quality materials tailored to withstand such conditions.

One key tip in choosing the right crusher blade is to thoroughly analyze the material you plan to process. Understanding the specific properties of the material helps in selecting a blade that can effectively manage the intended workload without compromising performance. Additionally, consider the blade geometry; different shapes and designs can enhance cutting efficiency and facilitate smoother operation, especially when dealing with varied material types.

Another important consideration is the operational environment. If the crusher will be used in extreme conditions, such as high temperatures or a highly corrosive atmosphere, opt for blades that are designed to endure such challenges. By carefully matching the blade specifications with the material properties and environmental factors, you can greatly improve the crusher's performance and reduce maintenance costs over time.

When selecting a crusher blade, durability and maintenance requirements are crucial factors that can significantly impact performance and longevity. A blade constructed from high-quality materials will generally offer better resistance to wear and tear, reducing the amount of time and resources spent on replacements. Look for blades made from hardened steel or alloys that can withstand the stresses of crushing materials. Additionally, the design of the blade plays a role in its durability; features like reinforced edges or specialized coatings can further enhance its lifespan.

Maintenance is another vital aspect to consider. A blade that requires minimal upkeep can save both time and money in the long run. Evaluate whether the blade has easily accessible components for cleaning and maintenance. Some blades are designed to be quickly disassembled for servicing, which can significantly streamline the process. Regular inspection for signs of wear, as well as appropriate lubrication practices, can help maintain blade efficiency. In conclusion, balancing durability with manageable maintenance requirements will lead to more efficient operations and optimal performance of the crushing equipment.

When selecting a crusher blade, the decision often boils down to the balance between cost and quality. Recent industry reports indicate that high-quality blades tend to last significantly longer—up to 30% more than their lower-cost counterparts—ultimately reducing overall operational costs. This enhanced durability not only minimizes the need for frequent replacements but also decreases the downtime associated with blade failures. Thus, the initial investment in quality may lead to substantial savings in the long run, especially for businesses that rely heavily on consistent production.

Moreover, the material composition and design of the crusher blade play a crucial role in its performance and cost-effectiveness. A study published in the Journal of Manufacturing Science and Engineering revealed that blades made from high-carbon steel offer better wear resistance compared to standard steel alternatives. Although high-carbon options may come with a higher upfront price, the extended lifespan and improved efficiency can result in lower total costs over time. For industries that depend on high throughput, the choice of blade becomes even more critical, as a well-chosen blade can streamline the crushing process and enhance productivity metrics significantly.