Leave Your Message

When selecting materials for industrial applications, the choice of the right Nickel Alloy is crucial to ensuring optimal performance and longevity. Nickel Alloys are known for their excellent resistance to corrosion and high temperatures, making them ideal for use in demanding environments such as chemical processing, aerospace, and oil and gas industries. However, with a wide range of Nickel Alloys available, understanding the specific requirements of your application is essential to make an informed decision.

This guide explores essential factors to consider when choosing a Nickel Alloy, including mechanical properties, environmental conditions, and compatibility with other materials. By evaluating these factors, engineers and decision-makers can identify the most suitable Nickel Alloy that not only meets performance criteria but also aligns with cost-effectiveness and availability. As industrial demands evolve, staying informed about the properties and applications of different Nickel Alloys will empower organizations to enhance their operational efficiency and meet industry standards.

Nickel alloys are essential materials used in various industrial applications due to their unique properties, including excellent corrosion resistance, high-temperature stability, and superior mechanical strength. Understanding the distinct types of nickel alloys and their characteristics is crucial for selecting the right one for specific applications. Broadly, nickel alloys can be categorized into two main groups: wrought and cast alloys. Wrought nickel alloys, such as Inconel and Monel, are often preferred for their ability to maintain structural integrity under extreme conditions. According to the Nickel Institute, over 60% of nickel production is consumed in alloy manufacturing, underscoring the importance of this material in today's industrial landscape.

The properties of nickel alloys vary significantly depending on their composition and processing methods. For example, nickel-chromium alloys exhibit exceptional resistance to oxidation and are frequently used in high-temperature environments, such as gas turbines and chemical processing plants. On the other hand, nickel-copper alloys, known for their excellent resistance to seawater corrosion, are commonly utilized in marine applications. Reports from industry analysts indicate that the global market for nickel alloys is projected to grow at a CAGR of around 5% through 2026, driven by increasing demand from aerospace, automotive, and energy sectors. This growth reflects the ongoing need for advanced materials that can withstand harsh working environments while maintaining reliability and performance.

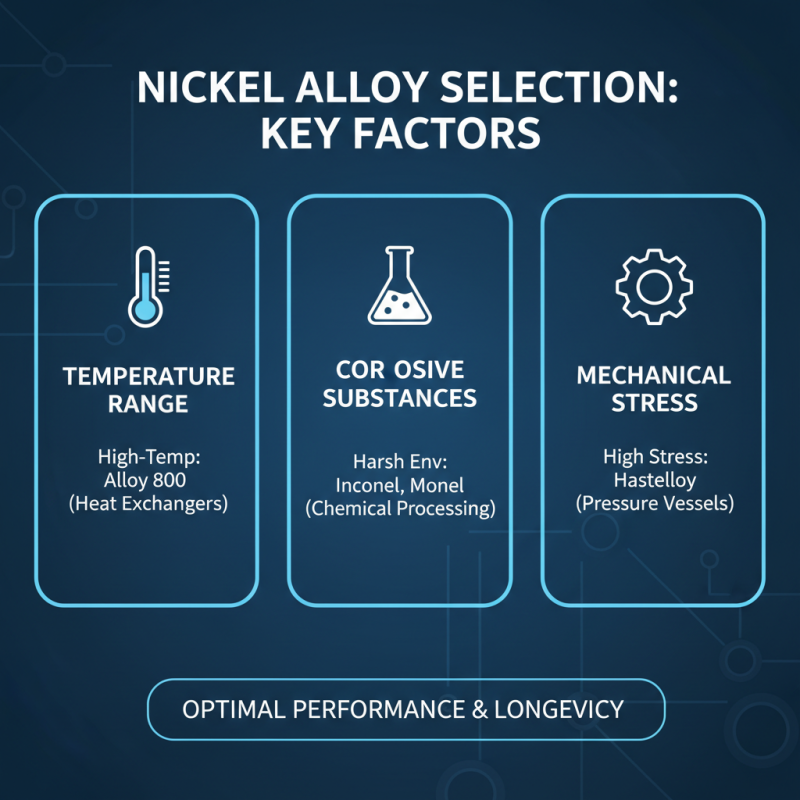

When selecting the right nickel alloy for industrial applications, several key factors must be considered to ensure optimal performance and longevity. First, it is essential to evaluate the specific environmental conditions the alloy will face. Considerations include the temperature range, exposure to corrosive substances, and mechanical stress elements. Alloys with superior corrosion resistance, such as Inconel or Monel, are often ideal for harsh environments, while those that excel in high-temperature applications, like Alloy 800, are recommended for heat exchangers and furnaces.

Tips: It’s crucial to consult industry standards and specifications when determining the suitability of a nickel alloy. Additionally, working closely with materials engineers can provide essential insights into the alloy's performance characteristics, enhancing the selection process.

Another critical factor to assess is the mechanical properties required for your application. This includes tensile strength, ductility, and fatigue resistance. For high-stress applications, alloys that offer high tensile strength and durability are necessary. In contrast, if flexibility and ease of fabrication are priorities, more ductile materials should be considered. Understanding the demands of your specific application will guide you in choosing an alloy that not only meets but exceeds performance expectations.

Tips: Perform extensive testing, including stress tests and corrosion assessments, to better understand how the selected alloy will perform in your unique application scenario.

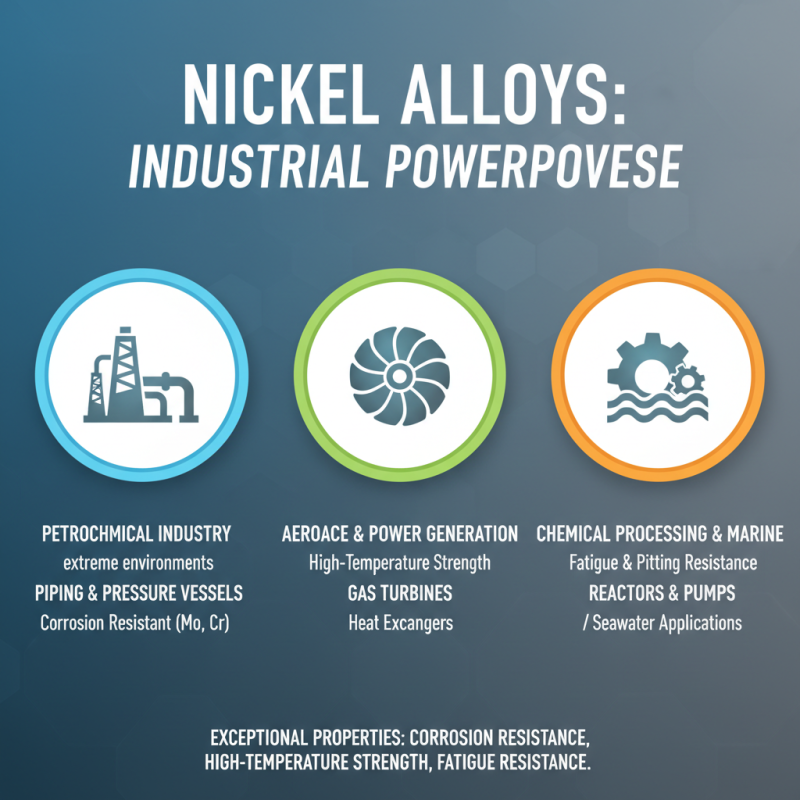

Nickel alloys are widely employed across various industrial applications due to their exceptional properties, such as corrosion resistance, high-temperature strength, and excellent fatigue resistance. In the petrochemical industry, for instance, they are often used in piping systems and pressure vessels that operate under extreme environments. These alloys must withstand corrosive media and high-pressure conditions, requiring specific grades that incorporate elements like molybdenum and chromium to enhance their capabilities against pitting and crevice corrosion.

In the aerospace sector, nickel alloys play a critical role in manufacturing components that experience high thermal and mechanical stresses. Turbine blades, for example, are often crafted from nickel-based superalloys, engineered to maintain their structural integrity at elevated temperatures. These materials must not only have high tensile strength but also display resistance to oxidation and thermal fatigue, ensuring reliability during operations in challenging environments. The choice of nickel alloy for such applications is crucial, emphasizing the necessity for materials that meet stringent performance and safety standards.

When selecting the right nickel alloy for industrial applications, one must conduct a thorough comparative analysis of the various available options to ensure optimal performance. Nickel alloys are renowned for their exceptional resistance to corrosion, heat, and mechanical stress, making them suitable for industries such as aerospace, chemical processing, and oil and gas. According to a recent report by MarketsandMarkets, the global nickel alloy market is projected to reach $12.76 billion by 2025, driven by the increasing demand for high-performance materials in demanding environments.

Different nickel alloys offer distinct advantages based on their composition and microstructure. For instance, nickel-copper alloys exhibit remarkable resistance to marine environments, while nickel-chromium alloys provide outstanding resistance to high temperatures and oxidation, ideal for applications in gas turbines and exhaust systems. A study published in the Journal of Alloys and Compounds demonstrated that the strength and corrosion resistance of nickel-based superalloys could be enhanced through the addition of elements such as molybdenum and tungsten, which are crucial for applications needing durability under extreme conditions.

Furthermore, understanding the specific requirements of an application, such as tensile strength, thermal conductivity, and resistance to specific chemicals, is essential. It has been observed that selecting the appropriate nickel alloy can lead to a reduction in maintenance costs and an extension of the service life of components. The 2021 ASM Handbook highlights that the right alloy choice can result in operational efficiencies, thereby saving companies significant financial resources in the long term. As industries continue to evolve, ongoing research into the performance characteristics of nickel alloys will remain vital in addressing the challenges posed by increasingly aggressive operating environments.

| Nickel Alloy | Corrosion Resistance | Temperature Resistance (°C) | Mechanical Properties (MPa) | Applications |

|---|---|---|---|---|

| Alloy 600 | Good | 1040 | 250 | Chemical processing, heat exchangers |

| Alloy 625 | Excellent | 980 | 550 | Aerospace, marine engineering |

| Alloy 718 | Good | 700 | 1000 | Oil and gas, aerospace |

| Monel 400 | Very Good | 540 | 350 | Marine applications, pumps |

| Inconel 825 | Excellent | 540 | 620 | Chemical processing, waste treatment |

When selecting nickel alloys for industrial applications, ensuring quality through rigorous testing and certification processes is paramount. These processes not only validate the material's performance characteristics but also ensure compliance with industry standards.

Testing methods typically include mechanical testing, corrosion resistance evaluation, and fatigue analysis, which help ascertain that the alloy will perform reliably under expected operating conditions.

Certification from recognized industry bodies further enhances confidence in the chosen materials. It signifies that the nickel alloy meets specific criteria regarding composition, strength, and durability, which are critical for high-stakes environments such as aerospace, marine, and chemical processing. Engaging with suppliers who adhere to these stringent testing protocols and hold relevant certifications can mitigate risks associated with material failure, ensuring that the selected alloy delivers optimal performance throughout its service life.