Leave Your Message

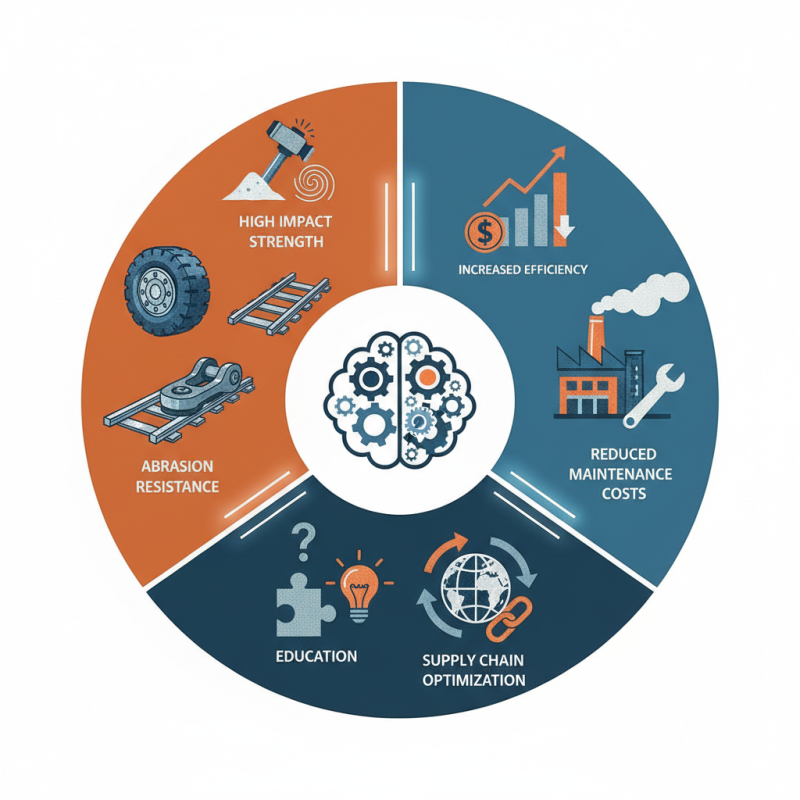

Manganese Steel Castings play a crucial role in various industrial applications. This unique alloy is known for its high impact strength and resistance to abrasion. It is typically used in heavy industries, such as mining, construction, and rail. According to a report by Research and Markets, the global manganese steel market is projected to reach $5 billion by 2027, driven by these essential applications.

The distinct properties of Manganese Steel Castings make them invaluable. They can endure extreme conditions while maintaining their structural integrity. For instance, they resist wear and tear, leading to extended service life. This durability translates to lower maintenance costs and increased efficiency. Notably, wear-resistant materials have been reported to reduce downtime by 30%, enhancing productivity.

Despite their advantages, challenges remain. Not all industries are fully aware of the benefits of Manganese Steel Castings. Education on their applications is needed. Furthermore, supply chain issues can impact availability. A better understanding of these castings could lead to more widespread use, ultimately benefiting many sectors.

Manganese steel is a unique alloy, primarily composed of iron and 12-14% manganese. This composition grants it remarkable properties. It is known for high impact strength and resistance to abrasion. Studies reveal that manganese steel can withstand severe wear, often outperforming traditional steel in demanding environments.

The toughness of manganese steel comes from its unique microstructure. When subjected to work hardening, it becomes even stronger under stress. Reports indicate that it can increase hardness by 200% during use. This is essential in industries like mining and construction, where equipment must endure extreme conditions. However, the challenge lies in its machinability; it can be difficult to cut and shape.

Manganese steel's ductility aids in complex applications. It retains flexibility under heavy loads, preventing catastrophic failures. Yet, manufacturers must balance its hardness with ductile properties. Using it indiscriminately may lead to premature wear. Thus, understanding its limitations is critical. Proper usage ensures that the benefits of manganese steel castings are fully realized, enhancing industrial applications without unnecessary failures.

Manganese steel castings play a vital role in industrial equipment. These castings provide remarkable wear resistance and toughness. Thanks to high manganese content, they can endure severe conditions. This means they are perfect for machinery involved in heavy-duty operations. Their ability to withstand impact makes them ideal for rock crushers and rail tracks.

However, not all manganese steel castings are created equal. Variability in the manufacturing process can lead to inconsistent quality. This can affect the performance and longevity of components. Additionally, while they are tough, they can still crack under certain stresses. Recognizing these limitations is crucial for making informed choices in industrial applications.

In machinery design, using manganese steel castings demands careful consideration. Finding the right balance between strength and elasticity is key. Operators must understand this material's behavior over time. Regular maintenance and inspections help address some challenges. With proper attention, the benefits of manganese steel castings can shine in industrial settings.

Manganese steel castings play a pivotal role in industries with high-stress applications. This material exhibits incredible strength and resilience. It can withstand heavy wear and tear, making it perfect for tough environments. Often used in machinery, these castings endure extreme impacts without cracking. The alloy's unique properties allow it to adapt to various stress levels.

Moreover, manganese steel can self-harden under conditions of impact. This means it becomes tougher when subjected to heavy loads. It’s a fascinating phenomenon that enhances its performance over time. However, even this highly regarded material has limitations. Manufacturing processes can be complex. Some may struggle with inconsistent quality during casting production.

Applications range from mining equipment to railway tracks. In these scenarios, safety is paramount. If the castings fail, it could lead to severe accidents. Therefore, regular inspections and quality controls are essential. The need for rigorous testing can't be overstated. Manganese steel is remarkable, but it requires careful handling.

| Property | Description | Applications |

|---|---|---|

| Hardness | Excellent wear resistance even in high-stress environments. | Mining equipment, Crusher parts |

| Ductility | Ability to withstand deformation under stress without breaking. | Railway components, Construction machinery |

| Impact Resistance | Capable of absorbing impacts without chipping or cracking. | Rock crushers, Shredder blades |

| Resistance to Abrasion | Prolonged life span in applications involving friction and wear. | Construction tools, Material handling equipment |

| Thermal Stability | Maintains properties at elevated temperatures. | Casting in hot environments, Industrial ovens |

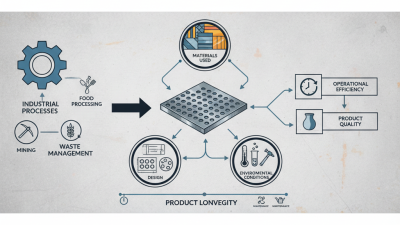

Manganese steel castings are vital in various industries due to their exceptional hardness and wear resistance. They are often used in mining, construction, and rail industries. According to a recent report, manganese steel castings can last up to three times longer than standard steel under abrasive conditions. This durability reduces the need for frequent replacements.

In the mining sector, they are essential for producing equipment like crusher parts and shovel teeth. These components endure harsh conditions and are subjected to significant wear. A study highlighted that manganese steel castings account for approximately 30% of the material costs in such machinery. In the construction industry, they are used in high-impact applications, such as bucket teeth for excavators. This application ensures that the machinery can handle rigorous tasks without rapid degradation.

However, reliance on manganese steel castings presents some challenges. The production process can lead to inconsistencies in quality. Some manufacturers struggle with achieving the desired properties consistently. Regular monitoring and investment in better technology are crucial to address these issues. Quality assurance remains a concern, as it directly impacts the longevity and performance of castings in demanding environments.

Manganese steel castings play a crucial role in various industrial applications. However, the production of these castings is not without its challenges. One major issue is achieving consistent quality. Variations in chemical composition can lead to weaknesses in the final product. This inconsistency often forces manufacturers to rethink their production methods.

Innovative approaches are emerging to address these issues. Advanced control systems and automation in casting processes help ensure more uniform output. Additionally, new alloy formulations are being explored to enhance durability without compromising ductility. Companies are experimenting with 3D printing technology as well. This allows for rapid prototyping and iterative design improvements.

**Tips:** Focus on material quality during sourcing. Regularly test samples to ensure they meet specifications. Monitor your casting processes closely. This can help minimize defects and improve overall output quality. Reacting to issues swiftly can also lead to innovations that enhance production efficiency. Keep an open line of communication within your team to share insights and improve techniques.

Manganese steel castings are critical in numerous industrial applications due to their exceptional properties. The bar chart above illustrates some key physical and financial properties of manganese steel, including tensile strength, hardness, wear resistance, machinability, and cost per kilogram. These properties demonstrate why manganese steel is highly valued in industries like mining, construction, and manufacturing.