Leave Your Message

When embarking on a project that requires Ductile Iron Castings, the selection process can be overwhelming. This material is renowned for its strength and flexibility. Choosing the right casting can significantly impact your project's success. Familiarity with Ductile Iron Castings can help you make informed decisions.

Understanding your specific requirements is essential. Different projects may need varying strengths, sizes, or finishes. Poor choices can lead to delays and increased costs. It's crucial to assess suppliers carefully. Some may not provide the quality you need, leading to regret later.

Consideration of the manufacturer's experience is vital. A well-established company often indicates reliability. However, emerging manufacturers with innovative processes should not be overlooked. Balancing tradition with modern techniques can yield fascinating results. Scrutinizing material specifications will ensure that your Ductile Iron Castings meet rigorous standards. In the end, thoughtful decisions will pave the way for your project's success.

Ductile iron is a crucial material in engineering and manufacturing. Its unique properties make it versatile across various applications. This iron alloy offers excellent strength, durability, and flexibility. These qualities are vital for components exposed to stress and heavy loads.

In construction, ductile iron castings are commonly used for pipes and fittings. They withstand high pressures and harsh environments. The material is resistant to corrosion, which further enhances its lifespan. However, choosing the right ductile iron casting can be challenging. The casting process must be considered. Variations in production can lead to differences in quality.

Additionally, while ductile iron is reliable, flaws can occur. For instance, improper heat treatment might result in brittleness. It's crucial to examine specifications and manufacturing methods. Consistency in quality control is essential. Engineers should be aware of these factors to ensure optimal performance in their projects. Ultimately, understanding the importance of ductile iron can lead to better decision-making in material selection.

Choosing the right ductile iron castings is essential for any project. The properties of ductile iron play a pivotal role in performance and reliability. One significant property is its tensile strength. Ductile iron exhibits impressive strength when compared to other materials. This characteristic makes it suitable for heavy-duty applications.

Another key property is ductility. Ductile iron can deform without breaking. This feature allows it to absorb shocks effectively. Such resilience is crucial in challenging environments. Moreover, the material's wear resistance impacts lifespan. It ensures castings endure in abrasive conditions.

However, there are also considerations. Not all castings are equal. Variations in composition can affect performance. It's vital to assess the specific requirements of your project. Understanding your needs will help you select the best options. Balancing these factors ensures your ducts perform as expected.

When selecting ductile iron alloy grades, several factors come into play. Ductile iron is known for its toughness and fatigue resistance, making it suitable for various industrial applications. According to the American Foundry Society, ductile iron can withstand high stress with a tensile strength ranging from 60,000 to 120,000 psi. Understanding these properties helps in determining the right grade for your project.

One crucial aspect to consider is the application environment. Will the castings face high temperatures or corrosive substances? For instance, grades like Ductile Iron 65-45-12 are ideal for high-stress scenarios, while grades like 80-55-06 might be better for moderate applications. It's essential to analyze the operating conditions before making a choice.

Tip: Always consult material specifications and data sheets from reliable sources to ensure compatibility with your requirements. Be cautious of assumptions; choosing a grade based solely on cost could lead to failures or increased maintenance.

Understanding the impact of alloying elements is also necessary. Elements such as copper and nickel can enhance toughness but influence cost. Striking the right balance is key. Not every supplier provides detailed data, making it vital to do your homework to avoid unexpected surprises.

Ductile iron casting is widely used in various industries. Understanding the casting processes is crucial for success. The process involves melting iron and adding elements like magnesium. This enhances the properties of the material, making it more flexible and durable.

There are different methods for ductile iron casting. These include sand casting and investment casting. Each method has its own benefits and limitations. Sand casting can be cost-effective for large parts but may lack precision. On the other hand, investment casting provides excellent detail but can be expensive. Evaluating your project’s needs is essential.

Consider the implications of each method. It’s not just about cost or time; quality matters too. Poor casting can lead to defects. Consider post-processing options as well. They can improve surface finish but add to the timeline. Each choice impacts the final product. Reflect on what matters most for your project.

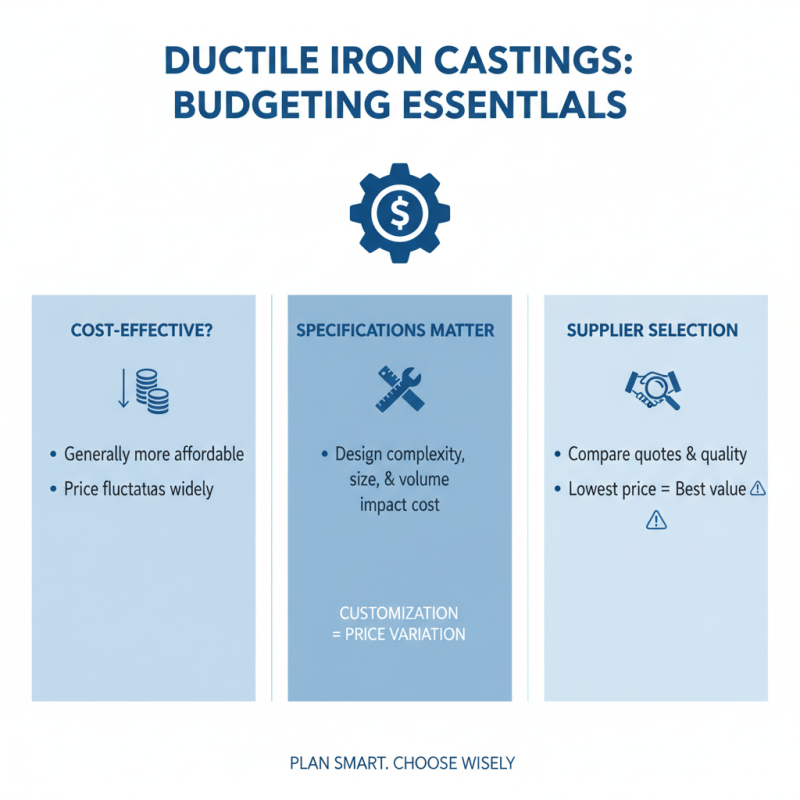

When planning a project, budgeting is crucial. The choice of ductile iron castings can significantly impact costs. These castings tend to be more affordable than alternatives, yet the price can vary widely. Depending on your specifications, the cost may fluctuate. Analyzing supplier options is imperative. Sometimes, the lowest quote does not guarantee quality.

Delays can arise if there are production issues. A lower-cost ductile iron casting may have hidden flaws. It is essential to consider potential risks. Inspecting samples can prevent costly mistakes later. Proper research is needed, as assumptions often lead to overspending. A project's timeline can tighten or stretch based on casting quality and reliability.

The economic impact extends to the project’s overall success. Efficient casting choices promote smoother workflows. Each decision builds towards your budget and timeline goals. For instance, investing slightly more for quality might yield better long-term results. Reflecting on these aspects helps ensure you stay on track. Ductile iron castings can be a cost-effective choice, but only if selected wisely.