QC Item

Front-end quality management

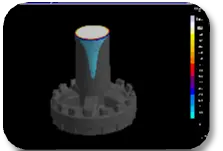

100% product MAGMA simulation.

Molding Instruction

Produced by the technical department, it clearly reflects the riser, chiller, runner and other elements in the form of a three-dimensional diagram. It also explains the applicable scope of new sand and recycled sand, the location of use of chromite sand, the thickness of sand paving, paint and casting letter requirements. Before the first production molding , technical personnel will provide briefing instructions to the operators.

Welding repair rate 3.4‰

Process design, pouring simulation

Molding

Smelting &Pouring

Check the ladle cleanliness for each lot

Check the state of dissolved waste for each lot

Process quality control

Routing Card

● One copy of each product, made according to the product process, including the product's MPP process, CTQ, special requirements, responsible departments for each sequence, inspection results before transfer, signature of the confirmer, confirmation time, etc., use magnets to attach to the product , all processes flow with the product.

● Rough machining NDT results, final performance results, rough machining dimensional results, and finishing inspection results require more conspicuous result judgment marks on the routing card by designated quality personnel.The transfer of any item with a non-conforming mark requires the approval of the quality director or above. Rough machining products must have 3 qualification marks, and finishing products must have 4 qualification marks before they can be put into storage.

Rough machining NDT results: Green indicates qualified, red indicates one or more items are unqualified.

Rough machining NDT results: Green indicates qualified, red indicates one or more items are unqualified.

Final performance results: Green indicates qualified, red indicates one or more items are unqualified.

Final performance results: Green indicates qualified, red indicates one or more items are unqualified.

Rough machining dimensional results: Green indicates qualified, red indicates one or more items are unqualified.

Rough machining dimensional results: Green indicates qualified, red indicates one or more items are unqualified.

Finishing inspection results: Green indicates qualified, red indicates one or more items are unqualified.

Finishing inspection results: Green indicates qualified, red indicates one or more items are unqualified.

Prevention and corrective management

Found undesirable issues

Analyze causes and formulate countermeasures

Implementation and verification

Measuring Dimensions

Visual Inspection

Detecting Sections

Assembly Test

Chemical Composition

Mechanical Properties

Hardness Test

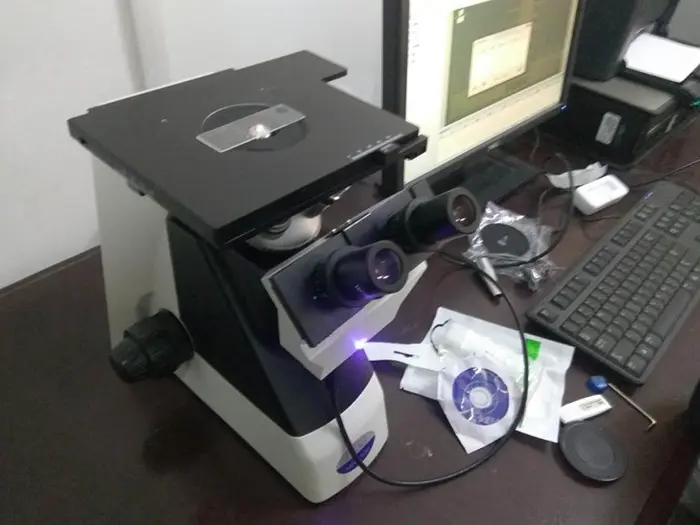

Metallographic Research

Ultrasonic Flaw Detection

Mechanical Properties Testing

X-ray control

Osmosis Test

We undertake to: