High Chrome Iron Steel

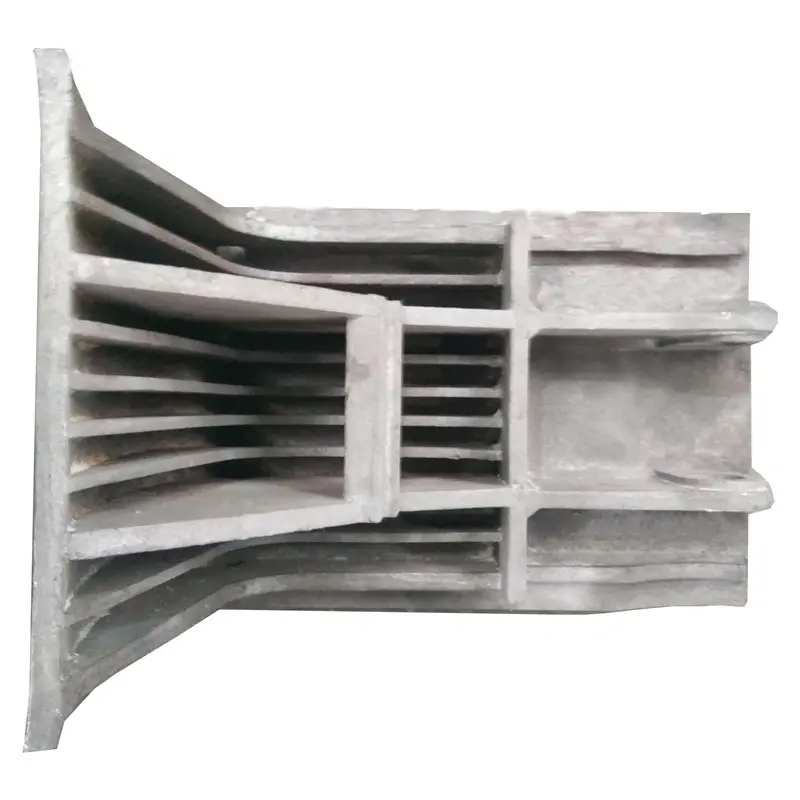

Main Products: Grates, guide rollers, crusher lining, track shoes, grate plate, screen plate, jaw plate, wear resistant liners, etc.

Main Process: Shell mold casting, wax loss casting, sand casting, foam loss casting, centrifugal casting.

Application: Biomass/waste to energy, steel shaft machine, ball mill, grate kiln, sinter/granulator, mineral process, cone crusher, pellet mill,...

High chrome cast iron

High chromium cast iron is a type of cast iron alloy containing high amounts of chromium. This material is known for its exceptional wear resistance, high hardness and excellent corrosion resistance. It is commonly used in applications that require high wear and impact resistance, such as mining, cement, and power generation industries. High chrome cast iron is also used for grinding media, pump parts and crushing equipment.

Standard And Class

EN 10295 DIN1.4710 1.4729 1.4740 1.4745 1.4776 1.4777

JIS G 5122 SCH1 SCH1X SCH2 SCH2X2 SCH3

ASTM A213 A335 A532 A297

Processes

Green sand process - for small to medium sized parts with low dimensional requirements (CT11-CT14, 0.2-200 kg)

Resin sand process - for medium to large size parts with high dimensional requirements (CT10-CT11, 100 kg-3000 kg)

Shell molding process - for small to medium sized parts with high dimensional requirements (CT7-CT9, ≤50 kg)

Foam molding process - for small to medium sized parts with complex structures (CT7-CT9, ≤100 kg).

Vacuum process - for medium and large parts with large surface roughness. (CT7-CT9, ≤10000 kg)

Advantages

Excellent wear resistance: High chromium cast iron has exceptional wear and abrasion resistance, making it suitable for applications in industries such as mining, cement and power generation.

Corrosion Resistance: It shows good resistance to corrosion, especially in aggressive environments, which extends its service life in harsh environments.

High temperature resistance: It can retain its mechanical properties at elevated temperatures, which enables it to withstand high-temperature applications such as furnaces and high-temperature equipment.

Good hardness and toughness: High-chromium cast iron combines high hardness with a certain degree of toughness, providing good resistance to impact and shock loads.

Disadvantages:

Brittleness: High chromium cast iron can be brittle, which can limit its use in applications requiring high ductility and impact resistance.

Processing Difficulty: Due to its hardness, it can be difficult to machine and fabricate, which can increase production costs and lead times.

Sensitivity to thermal shock: Rapid temperature fluctuations can cause thermal shock and potential cracking of high chrome cast iron parts, requiring careful handling of high-temperature products.

In general, high chrome cast iron has exceptional wear and corrosion resistance, making it suitable for use in harsh industrial environments, but its brittleness and difficulty in machining should be considered when selecting materials for specific engineering applications.